The difference between COB inversion and formal decoration

Date:

2024-05-31

With the popularity of inverted LED light sources in the market, more and more people are familiar with inverted light sources. However, for manufacturers of inverted COB light sources, what they have learned is definitely more comprehensive and professional than those outside the industry. Some users have also used inverted COB light sources. What is the difference between inverted COB light sources and formal COB light sources? Let's gradually analyze it!

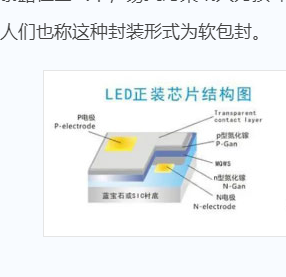

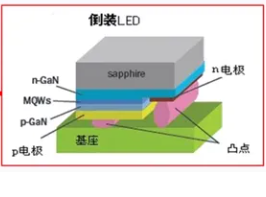

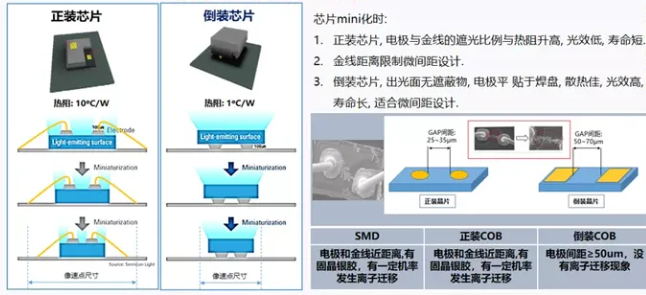

The reason why flip chip is called "flip chip" is relative to the traditional process of wire bonding connection. The traditional chip connected to the substrate through gold wire bonding faces upwards, while the electrode face of the flip chip faces downwards, which is equivalent to flipping the former over, hence it is called an "flip chip"! What are the advantages of inverted COB light sources compared to formal COB?

With the increasing maturity of formal LED products and the increasing difficulty of technology improvement, inverted LED technology has gradually been sought after by the industry in recent years. Due to its excellent heat dissipation without gold wire, but high cost, COB became the best stepping stone for flip flops to enter the market! Nowadays, inverted COB light sources have gradually entered the production lines of major packaging enterprises, and the industry has frequently praised that replacing formal packaging with inverted COB light sources will be an inevitable trend. Can inverted COB light sources really replace it? Let's see what do inverted COB light source manufacturers say? At present, compared to traditional COB light sources, flip chip COB light sources are comparable in price, but their market recognition is still quite good. However, the secondary optics of inverted COB light sources are not very easy to match, and the brightness is slightly 10-12% lower than that of the original. Although some manufacturers of inverted COB light sources can currently achieve a brightness below 8%, they still face these problems. However, I believe it is also a problem that inverted COB light source manufacturers can solve in the near future!

Inverted COB light source B and formal COB have their own advantages and disadvantages. From the current technology, although formal COB technology and process are also mature, efficient, and cost control is good, inverted COB light source can withstand higher driving current and optical density. The advantage of inverted COB light source is that the emitting surface can be smaller and the irradiation angle can be more concentrated, but it cannot cover the entire needs of commercial lighting applications. From a long-term perspective, Even if the inverted COB light source does not replace the formal one, it is bound to continue to develop and also go hand in hand with the formal one!

COB